HighSpeed Gyratory Crushing > Fine Cone Crushers

HighSpeed Gyratory Crushing –> Fine Cone Crushers Post navigation Previous Next thereby tending to minimize the ratioofvolumereduction The actual compressionratio in this chamber is about 15:1, which is lower than in either of the diagrams previously discussed and very much lower than the case of the standard crusher 【Advantages】The cone crusher machine is an advanced stone crusher with high power, large crushing ratio and high productivity It is suitable for fine crushing of various ores and rocks with mediumhigh hardness 【Cone crusher manufacturer】Compare to the wellknow cone crusher suppliers like , Telsmith, Sandvik, JXSC has our unique Cone Crusher JXSC MachineCS cone crusher is a kind of high efficiency spring cone crusher, with high capacity and high reduction efficiency Cone CrusherJiangsu Zhongbo Machinery Cone crusher is the commonly used equipment for intermediate and fine crushing rigid material,and has high efficiency, high capacity, low Cone Crusher High Capacity Crusher Mills, Cone A cone crusher in a secondary crushing application will typically work with a 35:1 to 5:1 reduction ratio Tertiary cone crusher configurations typically work with a reduction ratio of 25:1 to 4:1 The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per The pros and cons of cone crusher applications – QuarryThe concrete CD waste recycling process of “impact crusher + cone crusher + hooproller grinder” is also capable of handling brick waste In general, the secondary crushing using the cone crusher in this process with an enclosed crusher is a process of multicrushing, and the water content of waste will become an important affecting factorCone Crusher an overview ScienceDirect Topics

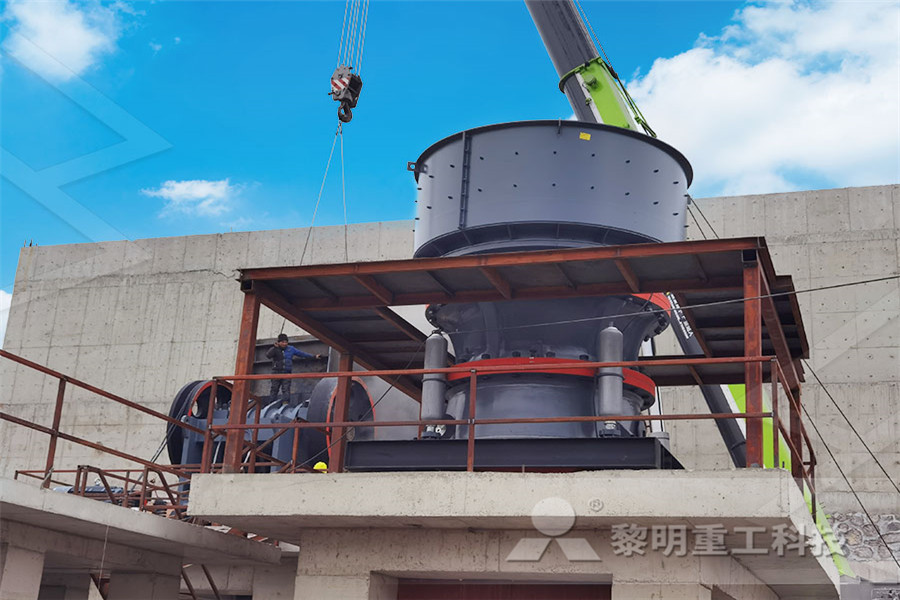

® HP100™ cone crusher Outotec

® HP100™ cone crusher is equipped with the latest highefficiency motors, making it efficient and ecological crushing machine ® HP100™ cone crusher produces finer products by limiting crushing stages, which lowers your investment cost and saves energy Hydraulic Cone Crusher Usage and Application Hydraulic cone crusheris widely used for secondary and fine crushing in the fields of mining, building materials, metallurgy and so on It can crush materials with middle and high hardness, such as Hydraulic Cone Crusher Cone crusher is definitely the most commonly used product in the mediumfine crushing stage of hard rock crushing (sometimes it is also used for coarse crushing according to the situation) It has good wear resistance and has many models, including spring type (Simmons) and single cylinder hydraulic , Multicylinder hydraulic, inertial cone crusher, etcThe Top 5 Must Know Granite Crushers (With GIF) After the primary crushing and the sandstone explosive crushing ,we can choose the impact crusher and cone crusher to proceed the midcrushing ac Promotion of Cone Crusher to Road Construction Two weixin 15:30:00 29 收藏Promotion of Cone Crusher to Road Construction Two